Special Lamp

Machines & Processing

Special Lamp

Machines & Processing

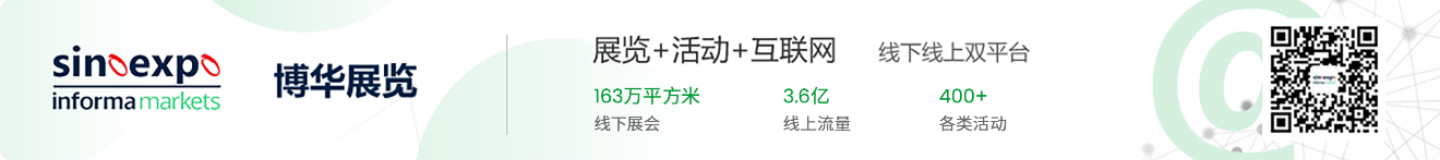

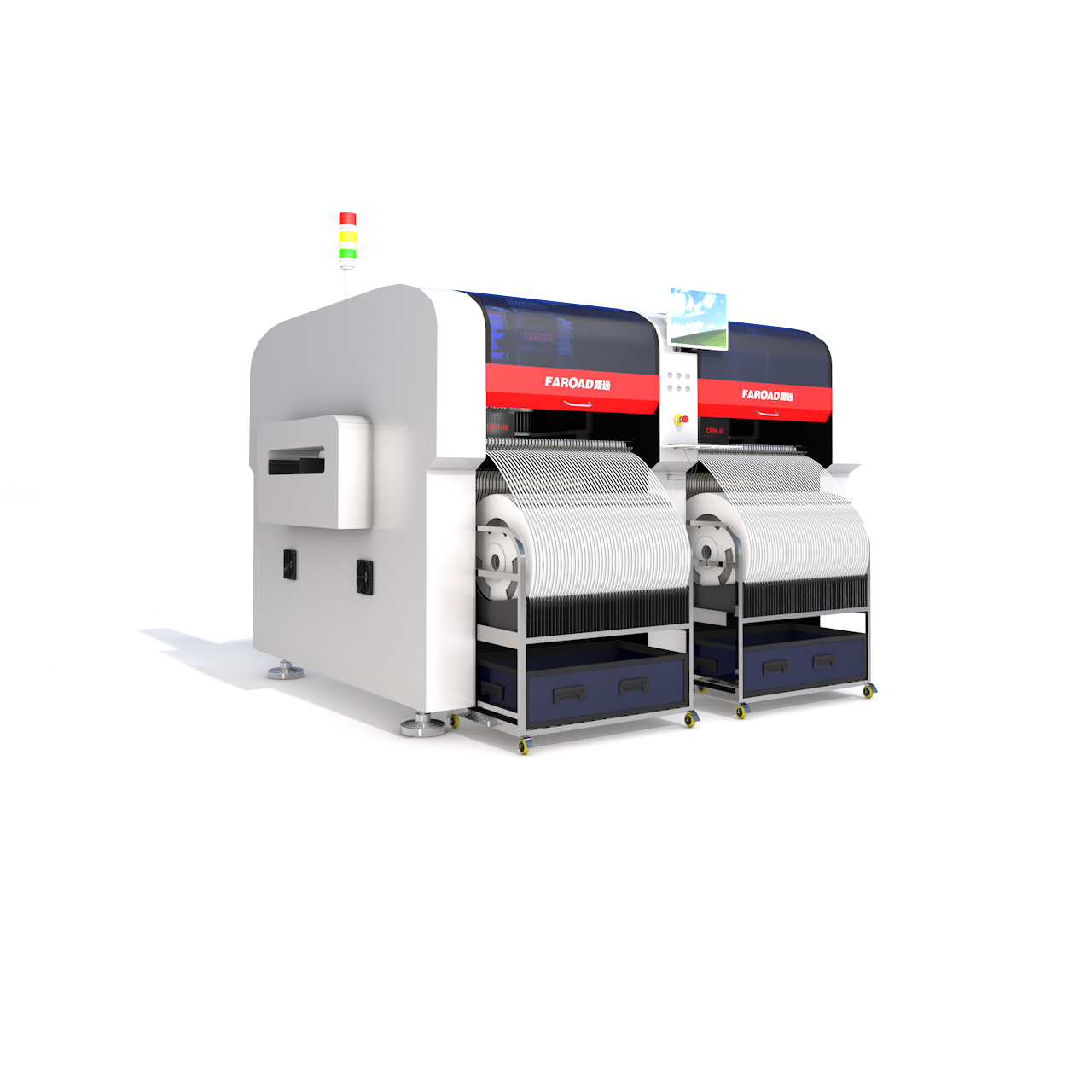

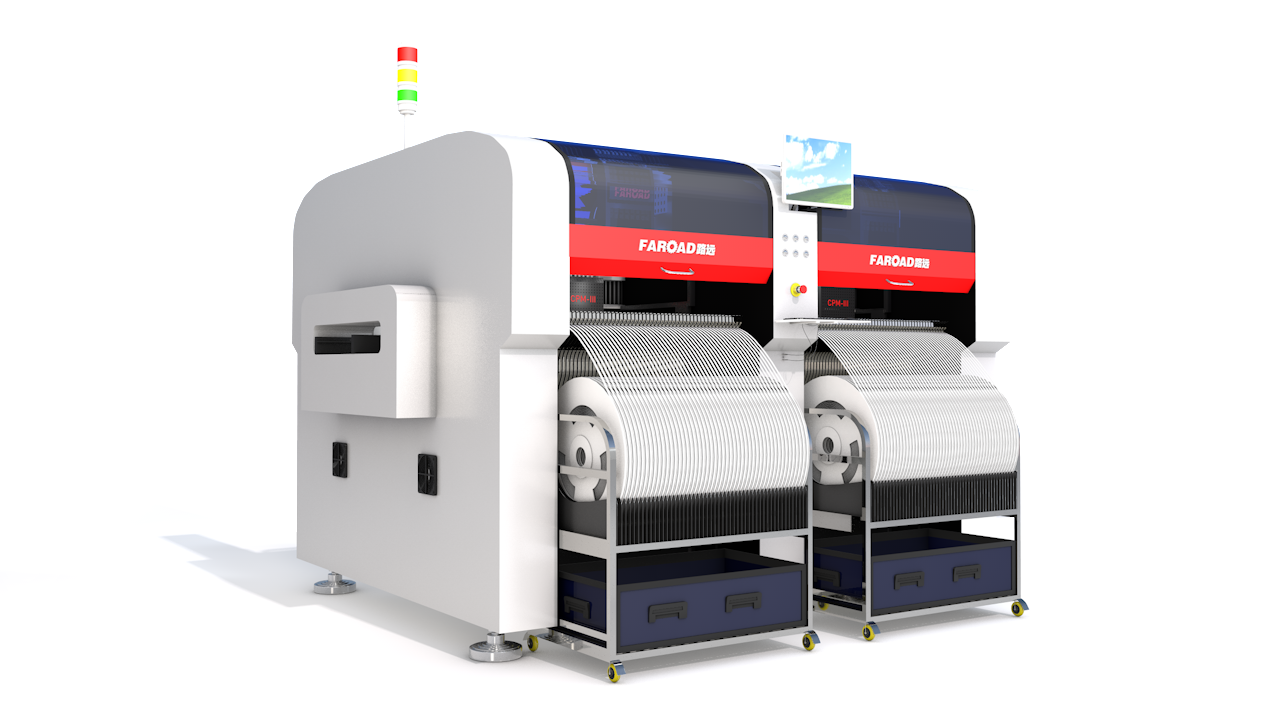

路远FAROAD CPM-Ⅲ高速贴片机

Faroad CPM-Ⅲ High Speed Pick and Place Machine

日本山洋直线电机使用设备达到更高精密更低磨损;

德国先进工业线性扫描相机实现零时差零停顿的高精密元件识别;

高精密热补偿系统实现实时监控贴装精度并自动修正;

吸嘴自动切换实现多种类元件同时兼容;

电机进料器,保证送料更精准,解决供料不稳定所产生元件丢弃;

中英文界面零时差一键切换,更广泛应用于国际市场。

Equipped with Japanese Sanyo linear motor owning higher accuracy and lower abrasion.

Advanced Germany industrial linear scanning camera can achieve high-precision recognition of the component without mistiming and stopping.

High accuracy thermal compensation system can monitor the placement precision in real time and modify the placement automatically.

Nozzles exchanged automatically ensures various components can be compatible.

Using electric feeder ensure the higher accuracy of feeding process, solving the component dump caused by unstable situation.

Fast switching between Chinese and English interface is more suitable for the international market.

参数规格 Parameter specification

|

贴装速度 |

65000chips/h |

|

贴装精度 |

±0.05mm |

|

基板尺寸 |

最小50mm×50mm,最大410mm×450mm |

|

基板厚度 |

0.4mm~5.0mm |

|

基板重量 |

0.68-3Kg |

|

PCB传送机构 |

三段式 |

|

工作头 |

16 |

|

料站数量 |

76站 |

|

进料器规格 |

8mm~56mm |

|

适用元件 |

从0201微小芯片~30mm大元件及各种电阻、电容、IC,BGA等。 |

|

电源 |

AC380/420/480V |

|

空气源 |

0.5~0.8Mpa |

|

控制系统 |

中英文操作界面Windows 系统控制平台 |

|

设备尺寸 |

L2250mm×W1880mm×H1550mm |

|

重量 |

2890Kg |

Parameter specification

|

Placement speed |

65000chips/h |

|

Placement accuracy |

±0.05mm |

|

Board size |

minimum 50mm×50mm,maximum410mm×450mm |

|

Board thickness |

0.4mm~5.0mm |

|

Board weight |

0.68-3Kg |

|

PCB transmission mechanism |

Three phrases |

|

Spindle quantity |

16 Spindle ×2 Gantry |

|

Feeder capacity |

76 slots |

|

Feeder specification |

8mm~56mm |

|

Applicable component |

From the tiny chip of 0201 to the large component of 30mm with various of resistors and capacitors, IC, BGA etc. |

|

Power |

AC380/420/480V |

|

Air source |

0.5~0.8Mpa |

|

Control system |

Windows platform + Chinese and English interface |

|

Machine size |

L2250mm×W1880mm×H1550mm |

|

Weight |

2890Kg |